Below is a list of the most commonly asked questions from our customers.

The Dolium one-way keg has a weight of 1.25kg.

Yes, Dolium one-way kegs are available prefilled with both nitrogen and CO2 based on the customer’s request.

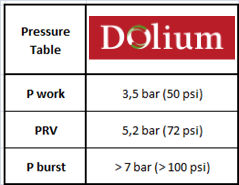

The maximum working pressure is 3,5 bar (50 psi) which is equal to stainless steel kegs.

The Dolium® kegs remain functional up to 5,0 bar. The Pressure Relief Valve (PRV) opens at 5,2 bar (+/- 0,2). For more details see our instructional video below.

The technical shelf life, in compliance with the brewer’s specifications, is proven to be 6 months. This is equal to returnable stainless steel kegs.

PET : Polyethylene terephthalate is a resin used for injection stretch blow moulding of bottles and containers for food and beverage. This is the basic resin for the Dolium one-way keg body.

HD-PE : High Density Polyethylene is a resin used for injection moulding of plastic parts. This is the basic resin for the Dolium one way keg’s top and bottom.

The Dolium one-way keg body is composed of Invista® PET Polyshield® blended with 5% of MXD6 Polyamide.

The polyshield component contains the oxygen (O2) active barrier, keeping the oxygen away from the product, whilst the MXD6 Polyamide is responsible for blocking the CO2 from leaving the keg.

The average loss of CO2 is 0.05gr/30L/month. For the oxygen content present in the keg over time please refer the graph below:

Dolium one-way kegs have 18 months of Barrier Protection from the assembly date indicated on the Pallet Label and on every Keg Bottom Label.

Dolium one-way kegs are available in 30 liter (7.93 US gallons) , 20 liter (5.28 US gallons) volumes and 12.5 liter (3.30 gallons), see our products page

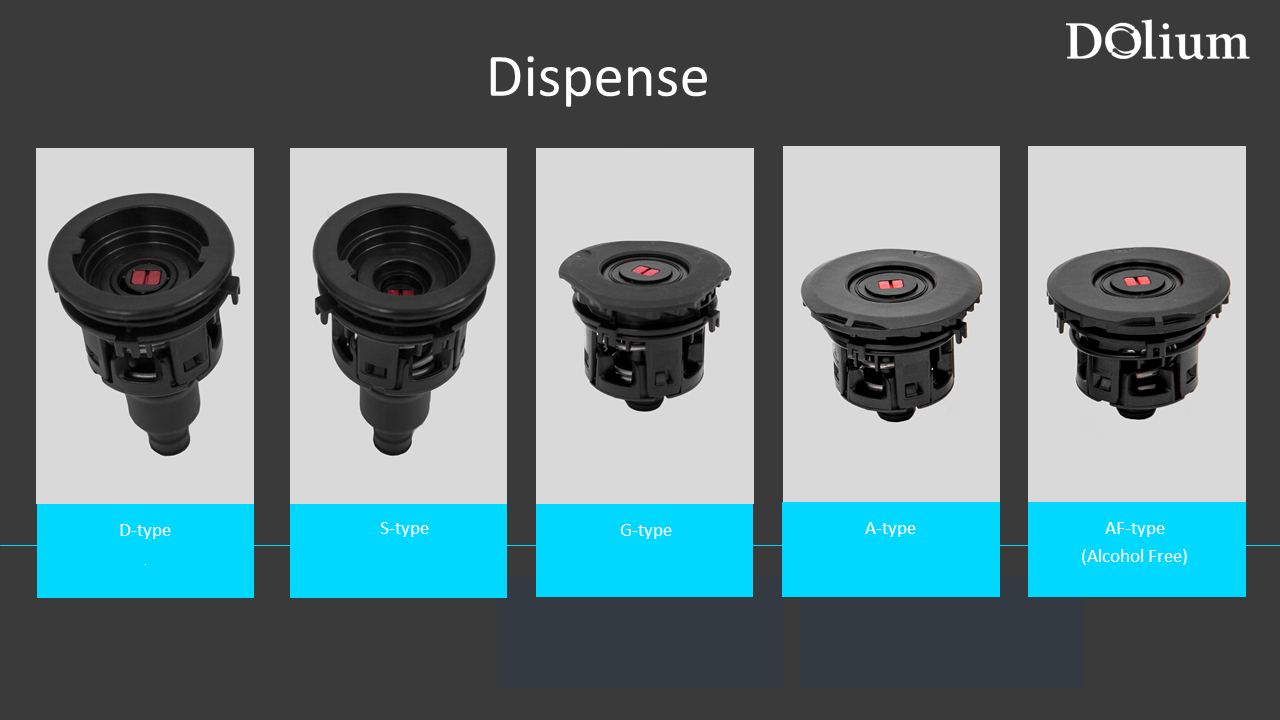

Dolium one-way PET kegs are equipped with either:

For all spear types the connection process is equivalent to stainless steel kegs.

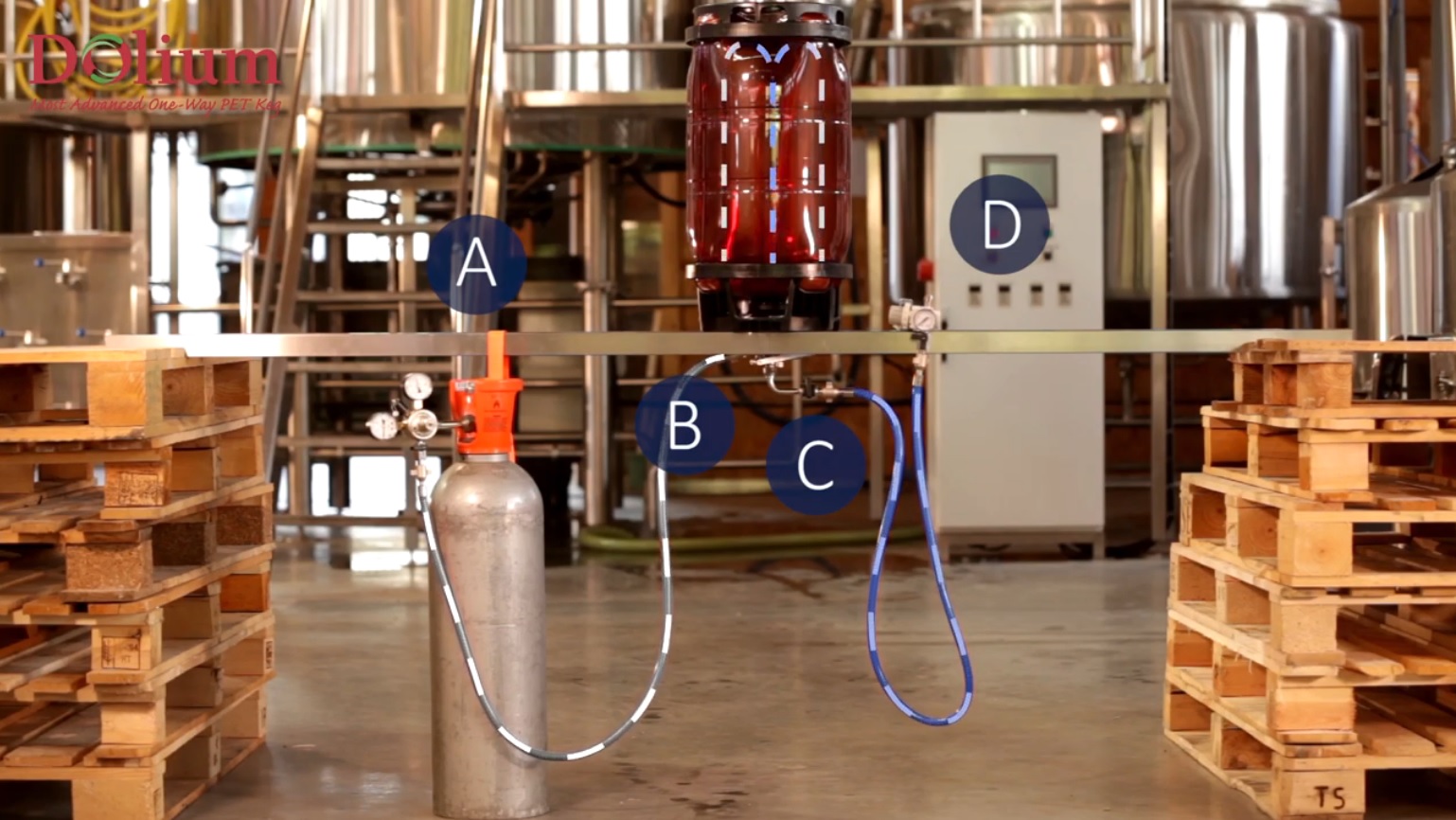

The Dolium one-way kegs can run on manual, semi-automatic, full-automatic, in-line and rotative filling lines.

Each filling line can differ from another. We can provide you with more technical details on request.

Dolium® can also provide samples for qualifying brewers for testing purposes.

Please Contact Us for more information.

No internal cleaning required. Our customers receive clean and sealed kegs. The Dolium disposable one-way PET keg is assembled using clean and sterile components in a clean room environment.

We recommend to rinse the outer spear parts by use of hot water (85°C for 2 seconds) or clean water (peracetic acid or chlorine dioxide) prior to opening the valve system.

Yes. Our customers receive CO2 or N pre-flushed and CO2 or N pressurized kegs.

Dolium® guarantees a CO2 or N concentration above 90%.

Therefore a final CO2 or N flush is required on the filling line prior to filling equal to practice with stainless steel kegs.

No, the Dolium one-way kegs can run on manual, semi-automatic, full-automatic, in-line and rotative filling lines at filling speeds equivalent to stainless steel kegs.

Dolium® kegs can be filled manually in straight up position or upside down equal to stainless steel kegs. For detailed instructions please Contact Us.

For detailed descriptions of pressure and temperature settings please Contact Us or consult our Handling & Safety instructions.

Dolium one-way kegs are delivered CO2 or N2 pressurized, a pressure test is recommended.

No cleaning or disinfection activity is required. A CO2 or N2 flush is still mandatory prior to filling.

Ensure that Dolium one-way kegs never get into contact with caustic soda or alkaline detergent solutions (a.o. lye, alkaline chlorine solutions, tensides) as PET is not compatible with these type of products.

The Dolium one-way keg is designed for a head space of minimum 2% of the nominal volume.

Please keep the beverage pressure below 3 bar with a minimum pressure difference of 1 bar between in and out.

Yes, the working temperature of the Dolium one-way keg is set between 0°C and 35°C.

Please check our Handling & Safety instructions.

Beverages packed in stainless steel kegs are always at their best being drafted and consumed as fresh as possible.

We promote the same for Dolium one-way kegs. A maximum period of 30 days should be targeted for using kegs and draft.

Once the keg has been emptied and disconnected it is still filled with CO2 or N gas under pressure.

Therefore we recommend depressurizing the keg as soon as possible in a well-ventilated area.

The depressurization procedure is simple and can be be done by turning the Pressure Relief Valve by 90 degrees with a flat head screwdriver.

Please check the neck carrier on the keg or our Handling & Safety instructions for a detailed description.

Once the keg is depressurized, you can break down the plastic by crushing, cutting or shredding.

Never put the keg outside as domestic waste! Once the keg is depressurized, it should be recollected, brought into the recycling circuit.

Please contact our sales team at sales@dolium.eu for a quotation.

Contact Dolium sales@dolium.eu and we’ll get in touch to run a simulation for you.

Dolium® kegs are more efficient than stainless steel kegs because of:

Please contact our sales team at sales@dolium.eu and we will be happy to connect you with the proper distributor or to process your request directly ourselves.

For qualifying brewers we have a program in place to provide free samples for testing purposes.

Dolium one-way kegs have the flexibility and compatibility required to fill manually or automatically.

If you are interested in testing the compatibility for your system please contact us for further details at sales@dolium.eu.

With manufacturing in Belgium and distribution throughout the globe, we can meet your needs no matter the country you are in.

Please contact sales@dolium.eu so we can best assist you.

The HS code is 39233090.

Yes, Dolium one-way kegs work with most products whether they are carbonated or still. Of course specifications such as saturation levels, alcohol content, and ingredients like oils and fats should be checked with Dolium® in advance